Indmar Serial Number Location

You obviously found out what the engine year was. What is the number on the back of your Shamrock? I don't know if there's any difference between mine and others, but the last two digits on my Shamrock serial number are 98, and I bought my boat in 1998.There is nothing obvious like that in my engine model or serial numbers that would indicate the year. I suppose that's coded in, if it's there at all. I think the engines may be stocked and installed a while after purchase, in some cases. It would make sense that they would have a Ford engine in stock over a year.Of course, an Indmar would have been a special order at that time, wouldn't it? My Mercruiser was a special order by the marina, since they were a Mercruiser repair shop.

Your situation does seem strange.Did you ever check your serial number with Shamrock? When it was KCS, I emailed Anita Strand and she sent me all the particulars attached to my Shamrock serial number, just to have all the numbers I could get from them.Charles. All boat manufacturers receive a price break if their material orders exceed certain numbers. Consider Shamrock. They must forecast production a year in advance which put them forecasting 1993 production numbers in 1992. What happened then? First Gulf War!The stock market dropped, fuel prices soared, boat sales slid.

The engine manufacturer probably made them and all the other boat manufacturers a screaming deal on engines so Shamrock loaded up. They then installed their stockpiled engines until inventory was depleted.About 35 - 50% of all Shamrocks have engines manufactured in years prior to the hull manufacture date.

Remember at Shamrock's peak production years they only made 200 boats. To get a decent break on engine prices they at times bought up to two years worth of engines. Plus shafts, props, instruments, etc.Tom. EnginesI thought I might chime in here.

KCS did use Indmar and PCM sea maxx's at the same time for a while in the mid 90's. Randy Moog, My plant manager had a 246 Open with an indmar motor in it. About the years not being the same, it is very common. Two things, one often The boat manufacturer has motors in stock for some time before they get used. Engine manufactureres also often change model years at a different time than boat manufacturers. Thirdly, The inboard motor companies often buy blocks from GM or Ford in large quantities.

This creates a difference in the years from the GM or Ford model years as well. I had a 1997 Mastercraft ski boat with an Indmar LT1, I had some problems and in my search for parts found out that my motor was actually a 1992 block made for a special line of LT1 camaro's. Anyway to make a long story short it is hard to know what year your motor is, but usually it will be different than your year of boat.Bo. This probably won't be of too much help, BUT. My 2003 246 WA was built in 2002 and has a Sea MAXX (ChevyTBI) that was built in 2001.the age of the hull I can varify by the Hull ID #, the engine age I'm basing only on the info packet I got when I purchased the boat new(definately not a conformation.but the engine identification serial numbers match up with one the code used in 2001.If I needed to find out what I had (for part replacements) I would give my engine serial number to Tim (The Engineman) and see if he could help.I'm surprised that Indmar couldn't help you.?Duane.

.O p e r a t o r ’ s M a n u a l.Indicates the presence of a hazard which result of your decision. CAN cause SEVERE injury, death or substan- tial property damage. Indmar Marine Engines.ENGINES COVERED The information in this manual applies to the following engine models: 5.7L Carbureted Indmar 6.0 Liter PFI Indmar 5.7L Vortec Malibu LS1 Corvette Malibu 350 Vortec MasterCraft LQ9 5.7L Throttle Body Fuel Injected Indmar 454 Carbureted Indmar 5.7L Vortec TBI Indmar 502 Carbureted MasterCraft 5.7L Predator.Dear Indmar Marine Engine Owner, Congratulations on selecting the finest marine inboard power available for your boat; Team Indmar welcomes you to our family of owners! Indmar proudly stands behind our products and is the first inboard manufacturer to offer a 3-year limited warranty.Appendix B – Engine Specifications. B-1 Appendix C – Limited Warranty.C-1 Indmar Marine Engines.They have current specifications, parts and the special equipment needed to service your Indmar engine and drive line.

To find your nearest Indmar dealer, please call (901) 353-9930 or visit our website at www.indmar.com. To ensure that the proper information is available, note the engine serial number.Indmar will not be liable for the resulting damages or injuries. Indmar Marine Engines.1-800-END-SMOG. Verdi prati handel pdf to word. www.arb.ca.gov need no additives for proper operation.

Expelled from the engine. INDM-A042 Your Indmar manufactured engine has a special environ-. Malibu LS1 engine 93 Octane mental label required by the California Air Resources.Air Filter (Flame Arrestor) Additives – The only additive that is recommended 3.

Ignition System by Indmar for use in your engine is Sta-Bil brand fuel Spark Plugs stabilizer. This additive helps preserve the fuel in your Electronic Ignition System tank and in the engine’s fuel system.All emission warranty parts are warrant- Current owner’s name, address, telephone, ed by Indmar for the entire warranty period of the engine, engine serial number and date of purchase unless the part is scheduled for replacement as required maintenance in the Operator’s Manual. Flame Arrestor: Clean every 100 hours. Replace as necessary. Spark Plugs: Replace every 300 hours or annually, whichever occurs first.

PCV Valve: Replace every 300 hours or annually, whichever occurs first. Spark Plug Wires: Inspect annually. Replace as nec- essary.

Indmar Marine Engines.Emission Component Part Numbers Following are the Indmar Part numbers for the Emission Maintenance Components: Engine Oil Filter Spark Flame Plug Distributor Distributor Plugs Valve Arrestor Wires Rotor Indmar 5.7 Carb 502 Malibu 5.7 Carb 505 751101 MasterCraft MCX.Select emission control parts from model year 2003- YOUR WARRANTY RIGHTS AND OBLIGATIONS 2008 inboard engines are warranted for 2 years. The California Air Resources Board and Indmar Select emission control parts from model year 2009 and Products are pleased to explain the emission control sys- later are warranted for 3 years.You are responsible for presenting your inboard engine to an Indmar Products distribution center as soon as a problem exists. The warranty repairs will be completed in a reasonable amount of time, not to exceed 30 days.Indmar Marine Engines.If you have questions about any of these procedures, see your Indmar dealer for assistance.

Exhaust – The drain hose must be connected. Transmission – The transmission oil cooler has one drain plug.4. Check engine oil for correct level. Refer to Chapter 6, Make sure the engine water intake is not Maintenance. Blocked by the trailer bunk. Blocked or restricted water flow may damage the engine.

Indmar Marine Engines.To prime:. Turn the ignition key ON for 5 seconds. Turn the ignition key OFF for 5 seconds. Repeat above eight to ten times Figure 1.4 – Raised Engine Cover Indmar Marine Engines.NOTICE Break-In Taking care now to break-in your new Indmar engine is The above procedure is only necessary for VERY important. When broken in properly, your engine the first time the engine is started or in the will last longer, run better and require fewer repairs over event the fuel tank is run dry.Your Indmar dealer is best equipped to check the engine immediately after break-in. After the break-in procedure is over, your boat may be operated continuously at any speed.Indmar Marine Engines.Operating a boat is a safe and enjoyable experience.

Indmar marine engines use gasoline for fuel. The area WARNING under the engine and around the gasoline tank and sup- ply lines is not open to outside air.DO keep your boat’s engine well-maintained and regularly check to make sure carbon monoxide detectors in the cabin are working properly. DO always wear a properly fitted life jacket while in or around water. Indmar Marine Engines.WARNING INDM-A007 Figure 2.1 – Pre-Start Check Points Your Indmar Marine Engine is cooled by 1. Verify boat hull and/or garboard drain plug are in pumping water from the body of water that place. The engine is being operated in through the 2.9.

Indmar Thermostat

Check alternator belt for wear and proper tension. Verify that exhaust hoses are in good condition and clamped tight. Ensure that the propeller shaft coupler bolts are tight. Verify engine mounts are tight. Indmar Marine Engines.Check wiring for signs of wear and abrasion. Verify throttle/shift control is functional and properly adjusted.

Verify steering controls are functional and properly adjusted. Verify battery connections are clean and securely fastened. INDM-A010 Figure 2.4 – Battery Connections Indmar Marine Engines.Indmar Marine Engines.1. Run the blower for 4 minutes to remove explosive sion resulting in death or serious injury to gasoline and battery fumes from the engine compart- you and your passengers. Indmar Marine Engines.(less than NOTICE 1100 RPM). Let engine warm up to normal operating temperature before accelerating. On carbureted engines it will be necessary to feather the throttle until the engine warms up.

Indmar Marine Engines.1. Check throttle lever (1, Figure 3-4) to make sure it is pulled out (or Neutral lockout button, 2, activated) so that boat is still in NEUTRAL. Wait for 30 seconds to allow starter motor to cool. Indmar Marine Engines.Hold key in START position for no more than 10 wiring and protection system. Before adding electrical seconds to clear extra gasoline from the engine. Equipment, consult your Indmar dealer.

When engine starts, immediately return throttle han- dle to IDLE position.Do not allow excessive amounts of water to remain in the bilge. Component damage due to water is not covered by the warranty. Follow the starting procedures outlined in Chapter 3, °F Engine Starting Procedures. INDM-A015 Figure 4.1 – Typical Temperature Gauge Indmar Marine Engines.Your engine has a safety feature that allows the engine to crank only in the neutral position. If during the starting process your engine will not turn over, make sure that the shift / throttle control is in the NEUTRAL position and try again.

Indmar Marine Engines.Avoid using the throttle when in reverse. This to your engine, drive line, or transmission caused by can force water backwards into the exhaust vibration is not covered by your warranty.

System and into the engine cylinders with major damage. Indmar Marine Engines.FUEL SYSTEM Before disconnecting the battery, make sure the battery switch (if equipped), ignition key and all accessories are The Indmar fuel system uses high quality marine grade in the OFF position.

These components will tolerate small amounts of water without sustaining damage. Your.INDM-A018 and sea strainer (if equipped) and hoses for blockage or Figure 4.5 – Typical Check Engine Light problems. Indmar Marine Engines.RPM is not harmful, even if the light is lit, provided that the V-Drive oil level is sufficient. If the oil level is normal and the light stays lit above 2000 RPM, take the boat to your Indmar dealer for service. ENGINE COOLING INDM-A019 Figure 4.6 –.The engine exhaust from this product con- tains chemicals known to the State of CAUTION California to cause cancer, birth defects or other reproductive harm.

Running the engine during the RPM reduc- tion phase may cause severe damage to your engine. Indmar Marine Engines.(propping) with the proper diameter and pitch. The Install a lower pitched propeller to increase WOT RPMs. Propeller which was supplied with your boat was chosen by the boat builder for best all-around performance under average conditions. Indmar Marine Engines.Humidity, barometric pressure and temperature have a noticeable effect on Indmar suggests that if you do require a different pro- the density of air since heat and humidity thin the air. Peller, consult the dealer you bought the boat from.

The.4-10 Indmar Marine Engines. Gasoline spills on your skin should be washed immediately with soap and water.

If gasoline spills on clothing, change cloth- INDM-A021 ing immediately. Figure 5.1 – Filling Fuel Tank. Avoid spilling gasoline. Clean spills with dry cloth and dispose properly.

Indmar Marine Engines.If your boat has not been used for more than 30 days with fuel in the tank (even stabilized fuel), the engine may run poorly until the “old” fuel is used up. Indmar will not pay for repairs to carburetors or fuel injection compo- nents that are inoperable or damaged from old and/or poor quality fuel.10% ethanol. If you operate your Indmar engine outside the USA or Canada, unleaded fuels may be difficult to obtain. Leaded fuels are not recommended as engine compo- CAUTION nents will last longer using unleaded fuel.Indmar Marine Engines.Your Indmar dealer is your best source for engine repair installed and tightened. If not, any electrical or ignition and maintenance. Indmar certified technicians attend. Be sure all fasteners you use are approved and rated for marine use.

Use of improper parts can cause component or engine failure which may result in death or serious person- al injury. Indmar Marine Engines.Tune Up Flame Arrestor Clean/Change Belts Inspect Shaft Alignment Check Spark Plug Wires. Inspect Raw Water Pump Impeller Inspect Replace Breather Hose. Clean PCV Valve.

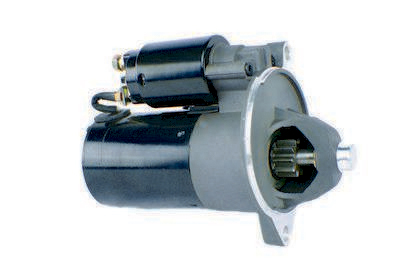

Replace Starter Bendix. Grease. Services best accomplished by your Indmar dealer.

Indmar Marine Engines.2 minutes after you turn off the engine to allow the oil to drain into the oil pan, giving you a more accurate reading. INDM-A025 Figure 6.3 – Engine Oil Fill INDM-A003 Figure 6.2 – Dipstick Indmar Marine Engines.To maximize engine life, change damaged.

The oil filter at every oil change. Indmar uses and recommends Pennzoil Marine 15W-40 Marine Oil API Service SL/SJ/CI-4, CH-4, CG-4 or equivalent. If engine is to be used on conditions below 20°.Oil Additives CAUTION Do not use oil additives. Indmar engines do not need oil Engine oil is hot. Be careful not to burn yourself. Use of recommended oil, along with regular oil and oil filter changes, will protect your engine adequately.Use only gen- engine. Because an inboard engine is completely uine Indmar replacement parts to ensure proper fit and enclosed, an uncontained backfire can be extremely protection against fire and explosion.Closed cooled engines are shipped from the engine temperature, and various connecting hoses.

The Indmar factory filled with a 50/50 mix of raw water pump pulls outside water through the intake, Sierra brand antifreeze and water. This mix- circulates the water through the engine and then ture provides freeze protection down to –26°.“OFF” and cool enough so no heat is registered on the temperature gauge. Only If cooling system is completely empty, see your Indmar after the engine is completely cooled is it safe dealer for assistance immediately to purge system.' out of compliance' with the emission standards the distributor, Indmar suggests that you do not operate in California. If you are experiencing drivability problems your engine until your dealer has reset the timing to origi- that may be related to the operation of your carburetor, nal specifications.The severe damage. Transmission fluid level should be HIGH checked each time the engine oil Indmar engines are is checked.

Fluid level is to be equipped with one of maintained at a level between the three types of marine “Full”.“ADD” and “FULL” or “H” and “L” (high and low); maintain fluid level between the two marks. CAUTION Check level immediately after turning engine off. Transmission fluid may be hot. Be careful not to burn yourself. INDM-A031 Figure 6.9 – Walters V-Drive Dipstick Location 6-12 Indmar Marine Engines.ELECTRICAL SYSTEM All Indmar engines are equipped with a 50 A circuit breaker (1, Figure 6-10) to protect the engine electrical system and components from overload. If the engine will not crank with the battery switch in the ON position, locate the red breaker reset button (labeled “50”) at the.If the breaker trips again, there is a problem with the WIRING electrical system.

Take your boat immediately to your Indmar dealer for repair. If during maintenance or inspection, it becomes neces- sary to move or reposition any of the engine’s wiring or.Damage that is the result of improper warranty! Storage is not covered under terms of Indmar’s limited warranty. To properly winterize your engine, you MUST be able to bring the engine up to operating temperature. To accom.Sierra Brand Anti Freeze (As required for Fresh operated without the flame arrestor secured, Water Cooled Engines Only) extreme care must be taken to ensure that the engine compartment is well ventilated and that no fuel leaks are present. Indmar Marine Engines.1.

Drain water from exhaust manifolds. Uncouple the hose quick disconnect and drain the manifolds. Indmar recommends that you leave the drain plugs out, or the hose uncoupled, until spring. Remove both hoses from the seawater pump on the INDM-A038 front of the engine.5. On Walters V-Drive equipped units, remove the two small square headed drain plugs from the front and rear of the upper housing.

Look for the words “Water Drain” on the housing. Indmar Marine Engines.3. Disconnect the large diameter hose that runs from boat is a good reminder to reinsert the plugs when the water-circulating pump to the thermostat housing. You recommission the boat in the spring.

Make sure all of the water drains from the hose. Indmar Marine Engines.4. If the coolant in the heat exchanger is not strong grease. Enough to protect the engine to the lowest anticipat- ed temperature, take your boat to your Indmar dealer General Power Package Preparation for replacement of coolant. Clean dirt, grime and grease from painted surfaces Fresh Water Cooled Engines of the engine and drive train.3. Coat the threads of the block drains and petcock mals. Clean as necessary.

Check for any damage or drains with pipe sealant and install in the engine evidence of fluid leaks. EFI engines have a knock sensor located in Indmar Marine Engines.3 '. 0 0 perature and re-inspect for leaks. If no leaks are found, the boat is ready for operation. INDM-A037 Figure 7.5 – Prop Shaft Flange Alignment Indmar Marine Engines.6. Lack of fuel at carburetor (Carbureted Engines Only) diagnosis charts to help pinpoint problems. Battery cables loose or corroded cases, you will need the assistance of your Indmar deal- 8.

Loose electrical grounds at engine er to correct the cause of the problem.6. Seized engine — turn crank pulley with socket and 4.

Engine in need of tune-up ratchet 5. Engine needs to be adjusted for high altitude operations 6. Engine needs to be adjusted for temperature extremes 7.